Indicators on Sheroz Earthworks You Should Know

Table of ContentsThe Best Guide To Sheroz EarthworksSome Of Sheroz EarthworksSheroz Earthworks - QuestionsRumored Buzz on Sheroz EarthworksNot known Facts About Sheroz Earthworks

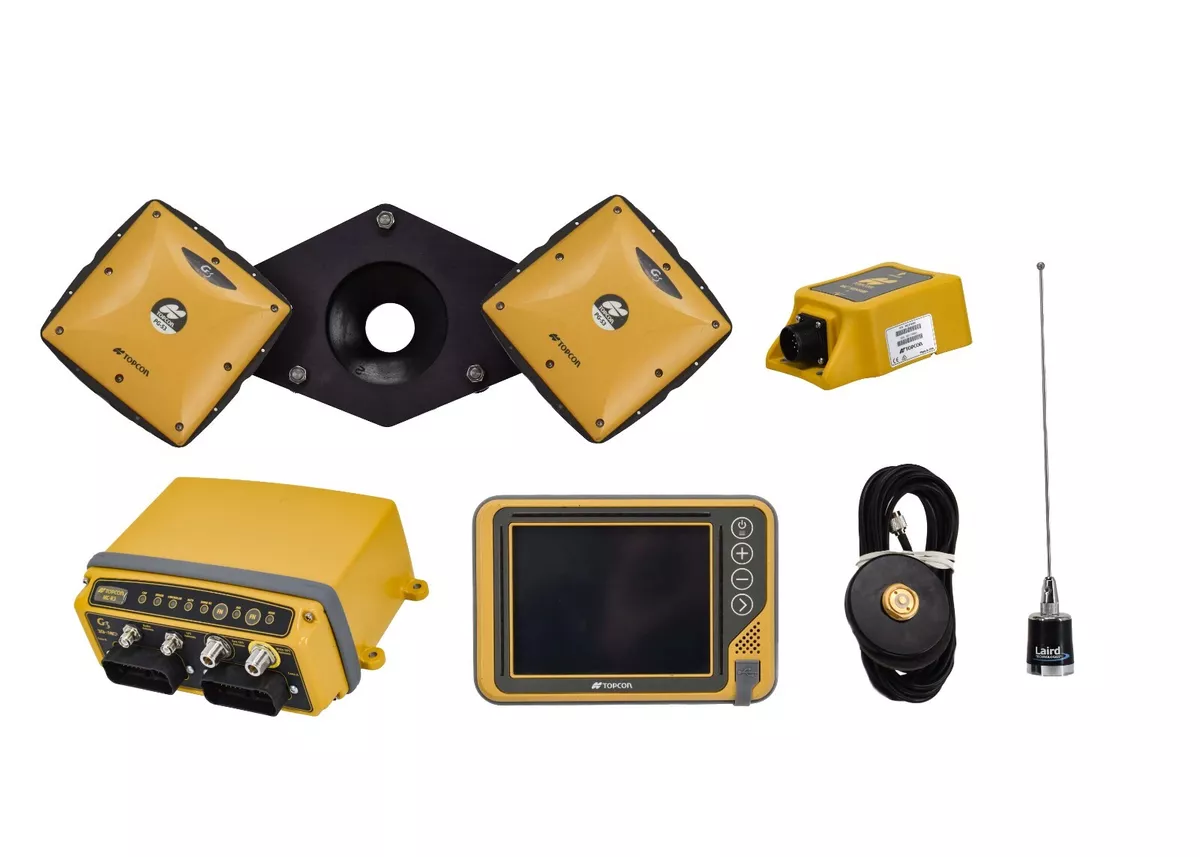

Getting the ground to just the appropriate level is no easy task. 3D maker control systems permit automated blade control, directing the dozer blade to exactly the best angle at specifically the appropriate spots. This system improves accuracy and efficiency by a huge margin. In addition, by ensuring level ground, it takes full advantage of security for workers once the building process begins.Scratching features somewhat like sleeping, but on a much finer and even more specific range. While dozers press big amounts of dirt out of the means to even out the ground, scrapes go back over the area to adjust it. topcon. Equipment control for scrapes functions simply like for dozers, routing the blade to just the appropriate position to accomplish a perfectly level cut.

Device control can include value to various agriculture jobs, consisting of: You can use the modern technology to intuitively keep track of and map field information in genuine time, making navigating and assisting your tools simpler than ever. Trick features consist of aided steering that eliminates a lot of the problem from the operator, water monitoring, yield surveillance and video clip electronic camera input.

Maker control is tough sufficient for heavy field use and provides the adaptability to perform numerous drain system applications. Attaining maximum vertical precision is crucial when rating and creating land for farming. Device control systems can manage this tough application quickly and effectively, allowing you to boost performance and lower downtime in the area.

4 Easy Facts About Sheroz Earthworks Shown

Experience measurable enhancements in vital locations like maker and possession scheduling, fuel usage and preventive maintenance. Strengthen task website security and various other vital processes by raising precision and integrity in vital mining procedures. Eliminate incorrect hand-operated field dimensions and increase reporting versatility in your geotechnical and ecological monitoring programs with these sophisticated data-capturing remedies.

No matter what the focus of your most current building job is, you can gain from equipment control. It can improve your leveling and hone your excavating, and it can do everything while giving you responses on where each vagabond is on the website at any type of provided moment. As a movie director, you can utilize the system software application to see the entire site at once and observe every place that is being altered in actual time.

SITECH Southwest can obtain you the machine control system you require to transform your construction procedure (https://www.dreamstime.com/floydoverbeck4500_info). As an accredited Trimble supplier, we provide top-quality equipment for all the construction processes listed above. Simply contact us today to obtain your maker control system!.

Not known Facts About Sheroz Earthworks

For this to function, turning lasers were set up to send signals that might be gotten by sensing units positioned on dozers or . This gave drivers the basic info they needed for their equipments. Yet, in comparison to modern maker control, these very early systems were still very restricted at offering a complete and accurate photo and were also usually as well pricey or complicated.

It is no trick that there is an absence of fresh talent going into the field. Particularly, contractors have difficulty bring in youths and, because of this, there are fewer operators getting in the career. Must this pattern continue, the market will be entrusted a scarcity of experienced and trustworthy drivers, which means that the quality and efficiency of jobs will certainly be influenced by a substantial abilities gap.

Surpassing simply supplying drivers with an aesthetic guide to bucket or blade position, automated machine control moves the blade to grade by talking with the device's hydraulics - trimble gps. Unlike with routine device control, automated device control technology places the responsibility for precision and rate strongly in the hands of performance-enhancing innovation

When checking out the present building landscape, it is clear that, in spite of its significant benefits, equipment control automation is not being taken on across all devices at an equal price. In truth, although automation is being accepted on devices like graders and dozers, the uptake has been a lot slower for excavators, with the adoption rate of automated machine control on these equipments still approximated at around 10% in Europe in contrast to a rate of over 50% for dozers.

The Facts About Sheroz Earthworks Revealed

Today, a rise in performance on excavators can be kept in mind as enhanced accuracy and reduced over-digging being reasonably very easy to verify. It is clear that the sector now needs to reassess the requirements for excavators. With the needs for efficiency enhancing and a shortage of experienced drivers, building and construction needs to welcome the benefits that investing in automated equipment control can bring.

If you are seeking to enhance your productivity with today's technology we are below to assist. Your existing team can be educated to carry out all facets of the established out and grab jobs of the daily website demands in a no nonsense strategy.

As expected, the excavator drivers are under an incredible pressure to supply an optimal efficiency while trying to achieve their efficiency goals at the exact same time. That is why all kinds of aid and renovations are much more than welcome regarding raised accuracy and optimum production. As constantly, modern technology is the trick.

The smart Trick of Sheroz Earthworks That Nobody is Talking About